The choice is clear

When considering flooring options for your home, the choice between real hardwood floors and alternatives like laminate and vinyl can significantly impact both aesthetics and long-term value. Here, we delve into the advantages of real hardwood floors, emphasizing their natural qualities, enduring beauty, long-term value, ability to be refinished, and renewable nature.

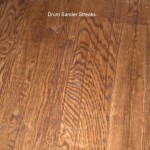

Natural Beauty and Authenticity

Real hardwood flooring offers an unmatched natural beauty that synthetic options like laminate and vinyl simply cannot replicate. Each plank of hardwood is unique, showcasing the natural grain, color variations, and texture that come from the tree it was sourced from. This authenticity adds character to any space, creating a warm and inviting atmosphere that enhances the overall aesthetic of your home.In contrast, while laminate and vinyl can mimic the appearance of wood, they often fall short upon closer inspection. Laminate typically features repeating patterns and lacks the depth and variation found in genuine hardwood. Even the highest quality laminate cannot match the richness and warmth of real wood, which can elevate the design of your interior.

Long-Term Value

Investing in hardwood flooring is often seen as a long-term financial decision. Hardwood floors not only increase the resale value of your home but also provide a lasting quality that can withstand the test of time. Unlike laminate and vinyl, which may need to be replaced after a few years due to wear and tear, hardwood floors can last for decades, making them a more economical choice in the long run.Moreover, the aesthetic appeal of hardwood can enhance the marketability of your home. Prospective buyers often prefer homes with real wood flooring, which can lead to quicker sales and potentially higher offers.

Refinishing Capabilities

One of the standout advantages of hardwood flooring is its ability to be refinished. Over time, hardwood floors can develop scratches, dents, and other signs of wear. However, unlike laminate and vinyl, which are often irreparable, hardwood can be sanded down and refinished multiple times. This process restores the floor’s original beauty and extends its lifespan, making it a sustainable choice for homeowners who plan to stay in their homes for many years

5.Refinishing allows homeowners to change the stain or finish, adapting the look of their floors to match evolving design preferences without the need for complete replacement. This versatility is a significant benefit that laminate and vinyl simply do not offer.

Renewable Resource

Wood is a renewable resource, and when sourced responsibly, hardwood flooring can be an environmentally friendly choice. Sustainable forestry practices ensure that trees are harvested in a way that maintains ecological balance, allowing for the regrowth of forests. In contrast, laminate and vinyl are made from synthetic materials, which can have a more significant environmental impact in terms of production and disposal.By choosing real hardwood, homeowners can contribute to sustainable practices while enjoying the benefits of a natural product that enhances their living spaces.

Conclusion

In summary, while laminate and vinyl flooring may offer advantages in terms of cost and ease of installation, real hardwood floors provide unparalleled beauty, long-term value, refinishing capabilities, and a commitment to sustainability. For those looking to invest in their homes and create a warm, inviting atmosphere, hardwood flooring remains the superior choice.